|

Each of Precise Automation's vision-guided, multi-axis robotic Guidance Motion Controllers integrates motion control, drives, IO, network communications and machine vision in an extremely compact and cost effective package. These controllers are based on a distributed control architecture implemented over Ethernet. This permits multiple controllers to be networked together to control mechanical systems that have from 1 to 32 axes. Our customers have integrated thousands of these units with their own mechanical devices to produce systems with easy-to-use high-level robotic motion control. |

|

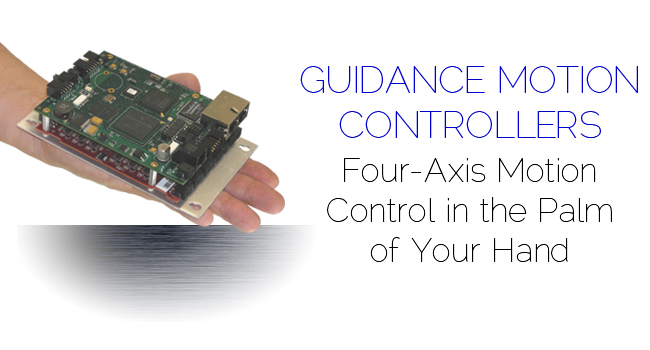

EXTREMELY SMALL WITH BUILT-IN

DRIVES FOR CONTROL OF A WIDE VARIETY OF ROBOTS A single controller can contain up to six motor drives in a remarkably compact design that can fit inside a robot's structure. This eliminates the need for controller cabinets, long and expensive cables, and costly connectors. Despite their small size, Guidance Controllers are extremely powerful and come with an extensive library of kinematic solutions. This enables Cartesian control of room size gantries, semiconductor wafer handling robots, high-speed packaging Delta robots, 6-axis articulated robots, and a variety of other devices including custom mechanisms. These controllers can drive DC brushless and linear motors and support a very wide range of absolute and incremental encoders. |

|

KEY FEATURES NOT FOUND IN OTHER MOTION CONTROLLERS

In addition to providing excellent motion control capabilities and multi-axis kinematics for control of complex mechanisms, Guidance Controllers offer many features not found in other products. These include: a web-enabled GUI to permit remote support; integrated machine vision capability to dramatically simplify the use of camera data to dynamically adjust an automation process; conveyor tracking capability; real-time on-the-fly path modification facilities; dynamic feedforward compensation to gravity balances links and greatly improve performance, and continuous path planning to reduce motion times and to generate smooth paths. |

|

POWERFUL SOFTWARE

Every Guidance Controller contains an embedded Web Server allowing access from anywhere in the world. Applications, as well as diagnostic information, can be uploaded or downloaded from remote sites, allowing collaborative development and fast customer service. These controllers support embedded applications with a powerful language modeled after object-oriented forms of the Basic Language. They can also be configured as a slave to a PC application using Ethernet as the communications interface, thus preserving legacy PC software. They also support sophisticated application software such as a CNC G&M code interpreter. |